LJBZ2025G vertical hollow glass flat pressure production line can complete the following functions: glass cleaning, aluminum frame placement, ordinary double glass, ordinary three glass, double glass aeration and three glass aeration.LJBZ2025G is a special equipment in aluminum hollow glass production.

Contact Now

ApplicationLJDM2545 clever vertical facet deleting gadget is used to delete the brink movie of the Low-e glass. The glass facet deleting gadget adopts imported servo manage system, positioning appropriately with easy operation. High high-satisfactory grinding wheels are durable, can produce neat and delightful grinding crack.

Contact Now

• 01 transfer section01 transfer section is inclined vertical structure. The transmission roller is wear- resistant, acid and alkali polyamine grease roller, adopting the stepless frequency conversion speed regulation and the glass can run smoothly at the appropriate speed. The foot switch can according to the work situation start and stop transmission at any time.

Contact Now

PERFORMANCESix sets of servo motors, British TRIO systemInlet-outlet with two-direction , 4 directions are availableAutomatically measure glass sizeAutomatically distinguish Low-E filmThe width of edge deletion is adjustablePLC control system, touch screen interfaceIntelligent control system, can recognize batch processing Deleting shaped glass Recognize Low-E fil

Contact Now

ApplicationLJDM2545 smart vertical edge deleting machine is used to delete the edge film of the Low-e glass. The glass edge deleting machine adopts imported servo control system, positioning accurately with smooth operation. High quality grinding wheels are durable, can produce neat and beautiful grinding crack.

Contact Now

High-Efficiency LJTJ2025 Automatic Sealing Robot 2.5m Vertical Insulating Glass Laminating Machine Could be ConnectedProducts DescriptionAutomatic Vertical Insulating Glass Sealing RobotAutomatic insulating glass sealing robot can be connected to 2.5m vertical insulating glass glue machineProduct descriptionThe automatic vertical insulating glass sealing robot evenly smears the mixed sealant on the outer channel of the insulating glass through the servo mechanism, which is helpful to improve the sealing and bonding performance of the insulating glass.Advantages & FeaturesBenefits & Adv

Contact Now

1. Vertical Edge Deleting Machine UsageVertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system.

Contact Now

Common problems and solutions in the production of insulating glassIn the production process of insulating glass, the frequently occurring problems are:1. When butyl rubber is extruded, burrs and not smooth

2. Butyl glue does not stick to aluminum strips and glass and loses its stickiness

3. After the second seal is completed, a cold flow of butyl rubber appears after some time

4. When butyl rubber is extruded, there will be glue breaking and blockage...Frequent problems in finished hollow glass products:1. Fogging inside the hollow glass

2. Condensation of hollow glass

3.

Contact Now

CNC automatic hollow glass aluminum spacer bending machineProduct description of automatic aluminum spacer bending machineAutomatic aluminum spacer bending machine LJZW2020Jinan Lijiang Glass automatic hollow glass aluminum spacer bending machine is a special equipment for the production of hollow glass aluminum frame, replacing the traditional manufacturing process.

Contact Now

Two-component glue coating machine is suitable for the last procedure of insulating glass production line, mainly used for two-component polysulfide glue, two-component silicone hollow glue coating.

Contact Now

PERFORMANCESix units of servo motors, British TRIO systemInlet-outlet with two-direction , four instructions are availableAutomatically degree glass sizeAutomatically distinguish Low-E filmThe width of part deletion is adjustablePLC manage system, contact display screen interfaceIntelligent manage system, can apprehend batch processing Deleting shaped glass Recogn

Contact Now

LJTJ2540 Automatic Vertical Insulating Glass Sealing Robot Could Making the Tempered glass is processed into Insulating GlassProduct DescriptionAutomatic Vertical Insulating Glass Sealing RobotJinan LIJIANG Glass Automatic Insulating Glass Sealant Sealing Robot Machine can apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.

Automatic Vertical Insulating Glass Sealing Robot Machine could apply the mixed sealant evenly to the outer channel of the insulating glass through the

Contact Now

The type of LJCJ01 smart insulating glass gas filling machine is special equipment for inflatable hollow glass. The device uses microcomputers and imported sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic adjustable concentration, high charging efficiency, the operation is simple.

Contact Now

Automatic Sealing Robot Vertical Insulating Glass Laminating Machine Could be ConnectedProducts DescriptionAutomatic Vertical Insulating Glass Sealing RobotJinan LIJIANG Glass Automatic Insulating Glass Sealant Sealing Robot Machine can apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.Automatic Vertical Insulating Glass Sealing Robot Machine could apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the seali

Contact Now

Smart insulating glass gas filling machine is special equipment for inflatable hollow glass. The device uses microcomputers and imported sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic adjustable concentration, high charging efficiency, the operation is simple.

Contact Now

APPLICATIONLijiang Production Line adopts the latest production technology, its main purpose is to create high-end quality, provide customers with the latest production technology and a complete set of product solutions, improve production efficiency, save production costs, and generate maximum benefits.At present, Lijiang hollow glass production line mainly adopts the new technology of air flotation to transport glass. This new technology is to prevent glass from being contaminated by wheels and leaving marks, so as to improve the quality of IG production. Detailed description1.

Contact Now

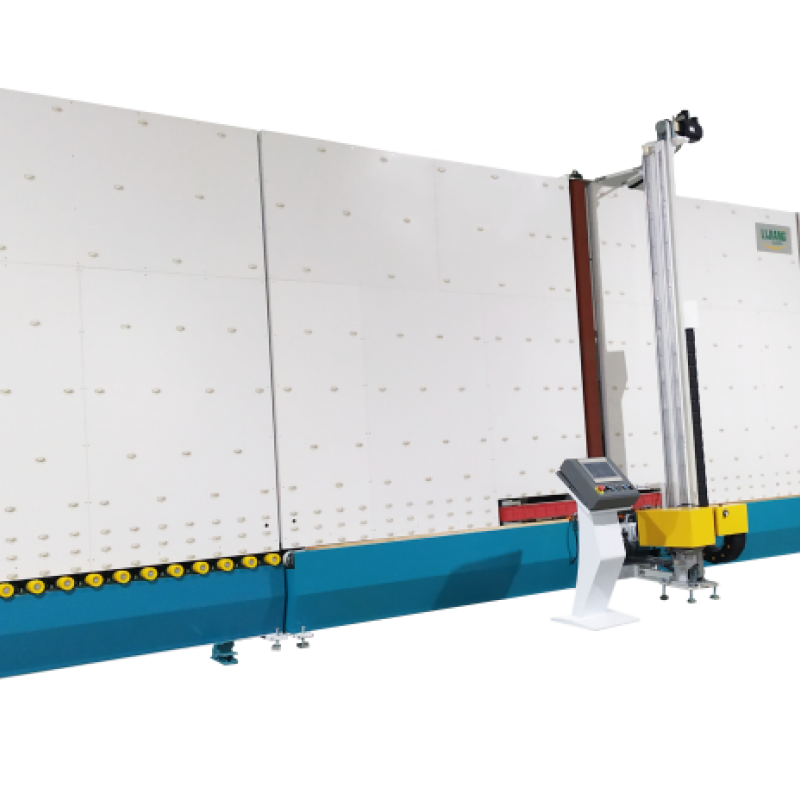

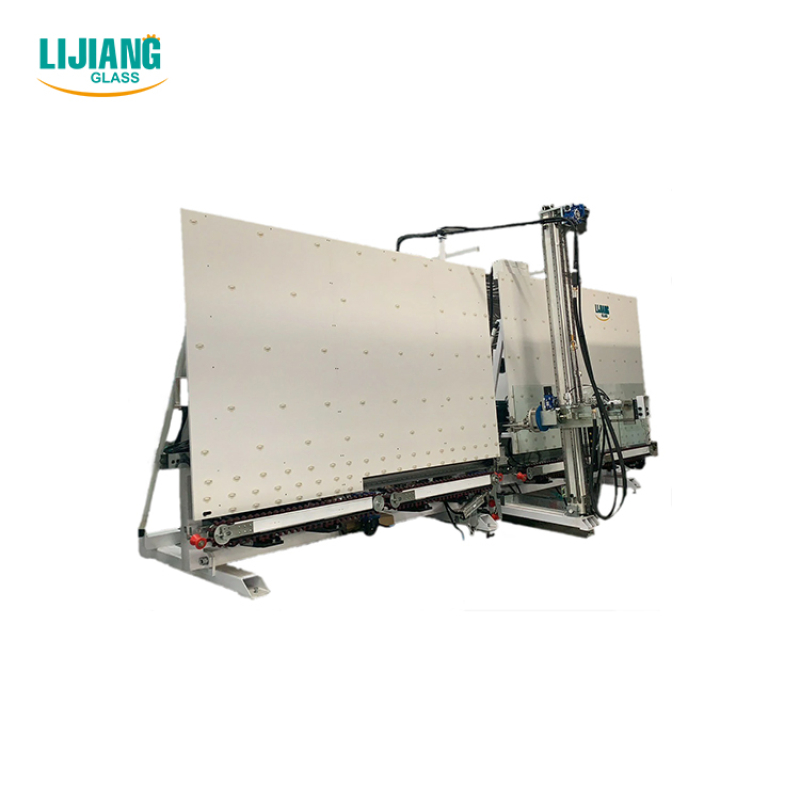

Vertical Insulating Glass Production line is used for making insulating glass for buildings, domestic home windows and doors, moreover for ship, refrigerator, freezer and so on. This IG line includes glass washing and glass pressing machine, it is able to make double / triple glazing glass, for aspects step glass.

Contact Now

Vertical insulating glass manufacturing line is used for making insulating glass for homes, home home windows and doors, moreover for deliver, fridge, freezer and so forth. this ig line includes glass washing and glass urgent system, it is able to make double / triple glazing glass, for facets step glass.

Contact Now

Vertical insulating glass production line is used for making insulating glass for homes, home windows and doorways, additionally for deliver, refrigerator, freezer and so forth. this ig line includes glass washing and glass pressing system, it is able to make double / triple glazing glass, for facets step glass.

Contact Now

Vertical Insulating Glass Production line is used for making insulating glass for buildings, windows and doors, also for ship, refrigerator, freezer and so on. This IG line contains glass washing and glass pressing machine, it can make double / triple glazing glass, for sides step glass. The optional function of filling argon gas is available, the air content is more than 90% at least.Technical data Max. glass size 2500mm*3500mm Min.

Contact Now

Application Min & max glass sizes can be optionalAdopt eight servo motorsAdopt japan anchuan servo manipulate gadget with strong overall performanceRoutinely degree glass length, glue intensity and glue velocity with linear adjustmentAdopt timing belt to maintain clean carry with correct positionSpares are produced with high standardization and excessive precision, make sure the machine may be used with long-term operatingThe glass corners are full without air bubbles, smooth surface, no need to Full automatic and high-efficiency machineNew scraper design, especia

Contact Now

LJBZ2025 Automatic Vertical Laminated Insulating Glass Double Glazing Production Line Details DisplayThe whole insulating glass production line usually includes 7 parts: (from right to left)1, The Loading section(with Low-E checking) 2, The washing and drying section(can wash Low-E glass) 3, The conveyor section 4, The checking and assembly section 5, The conveyor measure, and the sensor section 6, The press part with gas filling 7, The unloading section.The second part: is the washing and drying section.In this glass cleaning section, there are thre

Contact Now

Application Min & max glass sizes may be non-obligatoryUndertake eight servo motorsUndertake japan anchuan servo manipulate gadget with stable overall performanceAutomatically degree glass length, glue depth and glue velocity with linear adjustmentAdopt timing belt to maintain smooth bring with accurate functionSpares are produced with high standardization and high precision, make sure the machine can be used with long-term operatingThe glass corners are full with out air bubbles, smooth floor, no need to Full automated and excessive-efficiency deviceNew scraper design, par

Contact Now

Description of insulating glass production lineWhat does insulating glass production line do? Insulating glass production line is mainly for glass cleaning, plate pressing and inflation.

Contact Now