Desiccant Filling Machine

LJGZ2020

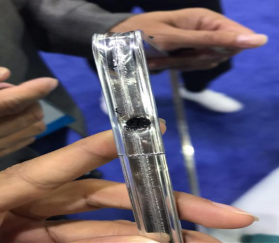

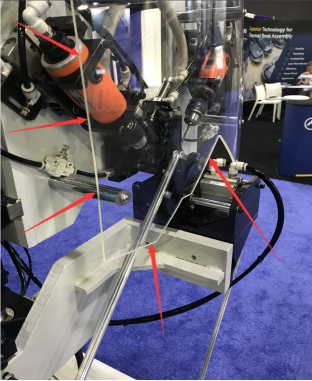

1. Desiccant Filling Machine can automatically achieve actions of drilling holes automatically in the spacer frames, filling desiccant and sealant.

2. Desiccant Filling Machine control system adopts Germany Siemens, so the speed of filling is quick and stable operation ensure the valid closure property of sealant.

3. Desiccant Filling Machine improves quality of insulating glass, it’s a necessary equipment in the process of insulating glasses.

Price

$7,000.00

Product Details

APPLICATION

Desiccant filling gadget can robotically acquire actions of drilling holes mechanically inside the spacer frames, filling desiccant and sealant. desiccant filling gadget manage device adopts germany siemens, so the velocity of filling is brief and strong operation make sure the legitimate closure assets of sealant. desiccant filling gadget improves best of insulating glass, it’s a necessary equipment within the system of insulating glasses.

1.All spare parts have ID Number for offering the convenience in after sales service. | 2. Machine height can be adjusted according to the size of spacer frame. |

|  |

| 3. Auto drilling, filling and sealing function | 4. Protection device for machine head. |

|  |

5.Touching screen interface,simple and visible ;Filling time can be adjusted according to the size of spacer frame in the touch screen. | 6.All the electrical wires have the ID number,it can match with specification , also it will be very easy for the further communication in the after sales service . |

|  |

7.Desiccant automatically loading from the Materials bucket.

(When the material was used up the sensor will alarming, desiccant will automatically loading )

Main technical parameter

Name | Brand | Name | Brand |

PLC | German SIEMENS | Triplet | TAIWAN AIRTAC |

Low voltage electrical apparatus | German SIEMENS | Solenoid valve | TAIWAN AIRTAC |

Sensor | Korea AUTONICS | Gas driller | Taiwan BOA |

Guide | Taiwan TBI | Switch power | Taiwan TEND |

Filling aluminum frame’s maximum size | 2000mm*2000mm |

Filling aluminum frame’s minimal size | 300mm*250mm |

Article aluminum specifications | 5.5-26.5mm |

Air source | ≥0.65MPa |

Power supply and power consumption | AC220V 50Hz 1.8KW |

Molecular sieve diameter needed | 0.5-0.9mm |

Dimension | 1350mm*1050mm*3600mm |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close