Automatic Spacer Bending Machine System

LJZW2020 / LJZW2020A

1. Adopt the servo control feeding system, spacer frame size can be adjusted with an accuracy of 0.1 mm/m

2. CNC bending angle control system with adjustable accuracy of 0.1°

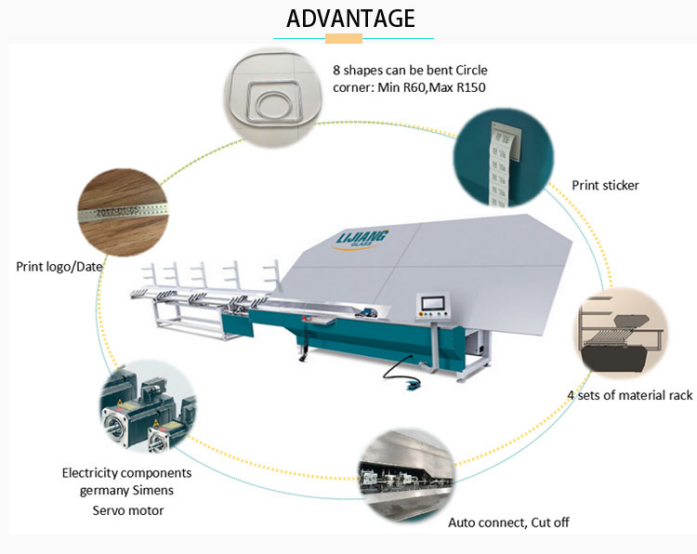

3. Set up four groups of spacers storage units

4. Aluminum bar with multiple sizes can be selected at will

5. Automatically adjust the bending speed according to the size of the aluminum frame to avoid the deformation of 6. The large frame and ensure the high speed and continuity of the small frame

Price

$9.99

Product Details

PERFORMANCE

Adopt the servo manipulate feeding tool, spacer frame duration can be adjusted with an accuracy of 0.1 mm/m

CNC bending attitude manipulate tool with adjustable accuracy of 0.1°

Set up four companies of spacers storage units

Aluminum bar with a couple of sizes can be determined on at will

Automatically regulate the bending speed regular with the size of the aluminum frame to avoid the deformation of the huge frame and make certain the immoderate speed and continuity of the small frame

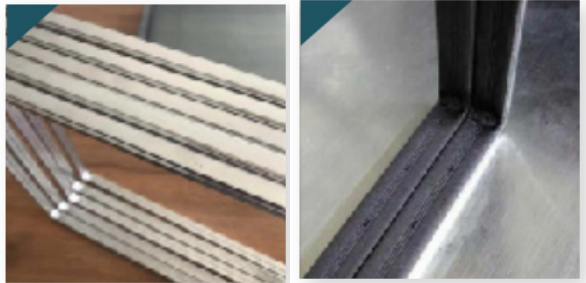

Automatic non-forestall connection of spacer, decreasing spacer, avoidance of spacer bar joint

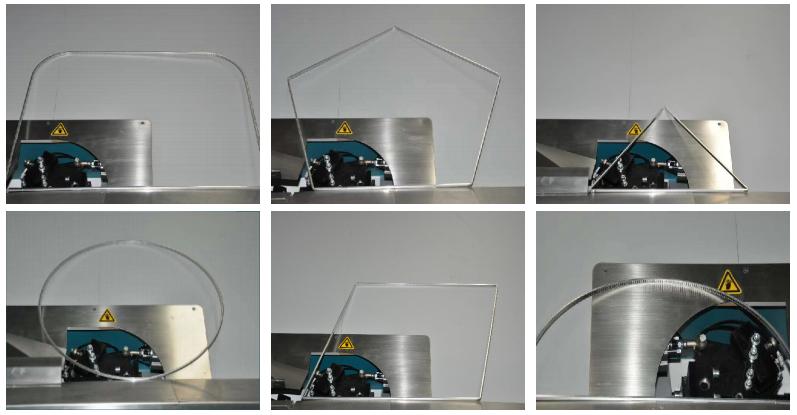

No material spark off, sleep spark off, fault spark off, art work spark off, unreasonable records refuse processing and spark off Support arc-customary aluminum frame and precise customary aluminum frame bending

USB function, which can read excel directly

Connect with ERP(optional)

Options

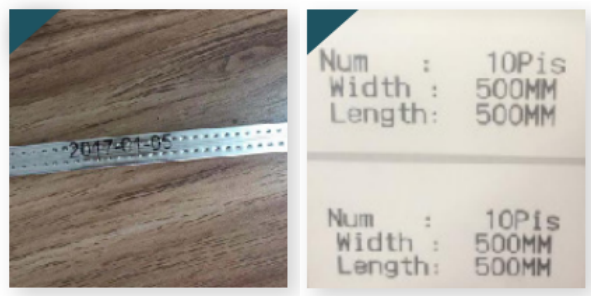

Automatic printing code Automatic printing label

Bending stainless steel spacer Bending warm edge spacer

PARAMETER

| Max. bending size | 1800*2000mm(in once)/2500*4000mm(in twice) |

| Min. bending size | 150*300mm |

| Aluminum spacer width | 5.5-26.5mm |

| Spacers racks | 4 |

| Spacer size error | ±0.5mm |

| Angle error | ±1° |

| Conveying speed | 1250mm/s |

| Air pressure | > 0.65MPa |

| Voltage | 380V50Hz 3P |

| Total power | 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

| Weight | 1580kg |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close