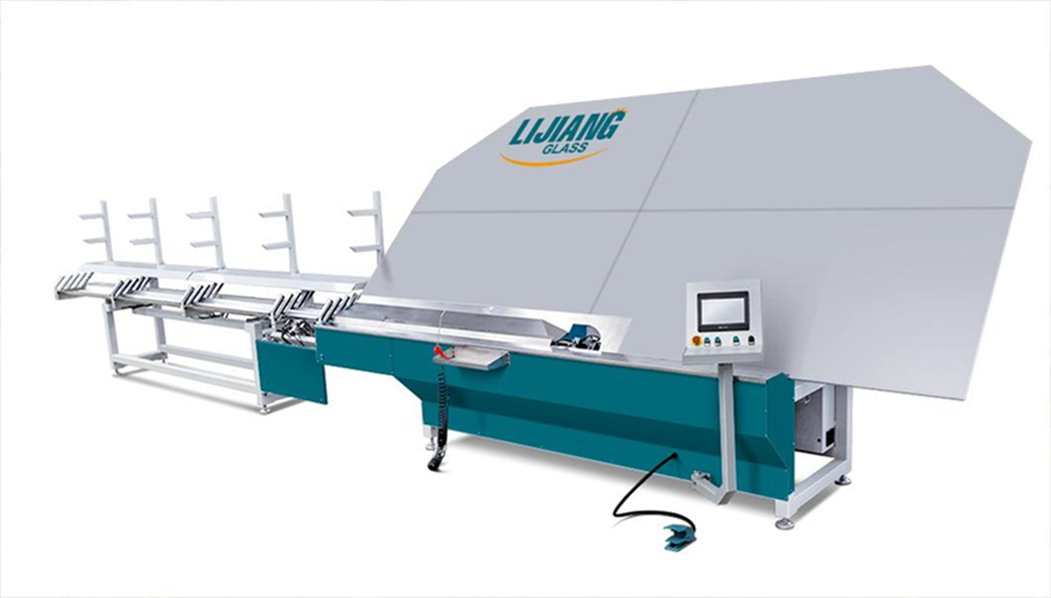

LJZW2020A Automatic Insulating Glass Aluminum Spacer Bar Bending Machine

1. Automatically avoid the connection while bending and cutting

2. Pause/set device, convenient for machine malfunction maintenance, protect the servo motor

3. USB input function, read the excel format file directly, etc (optional)

4. Spacer printing function (Optional)

5. Can bend aluminum spacer, Technoform, Alupro, Thermax, Swisspacer, and Stainless steel (Stainless steel optional)

6. Automatic drill glass filling hole (Optional)

Price

$30,000.00

Product Details

LJZW2020A Automatic Insulating Glass Aluminum Spacer Bar Bending Machine

LIJIANG production line adopts the latest technology, its main purpose is to create high-end quality, provide customers with the latest production technology, improve production efficiency, save production costs and produce maximum benefits.

Now LIJIANG mainly has two kinds of IG lines with different two different technologies. One uses transfer wheels to transport glass, and the other is a new technology that uses air-floating technology to transport glass. This new technology is to prevent the glass from being contaminated by wheels and leaving traces, so new technology is used to improve the IG production’s high quality.

Benefits & Advantages

Germany Siemens PLC control system

Germany Siemens CNC servo control system

Four spacer size storage units

CNC servo control feeding mechanism

Auto furnishing and cutting spacer function

The auxiliary function of adjustment for bending Large aluminum frame

Can be optional to different specifications and sizes of aluminum space

Supporting bending for different shapes' spacers Continuously

Separated guard board outside of bender

Automatically avoid the connection while bending and cutting

Benefits & Advantages

Germany Siemens PLC control system

Germany Siemens CNC servo control system

Four spacer size storage units

CNC servo control feeding mechanism

Auto furnishing and cutting spacer function

The auxiliary function of adjustment for bending Large aluminum frame

Can be optional to different specifications and sizes of aluminum space

Supporting bending for different shapes' spacers Continuously

Separated guard board outside of bender

Automatically avoid the connection while bending and cutting

Pause/set device, convenient for machine malfunction maintenance, protect the servo motor

USB input function, read the excel format file directly, etc(optional)

Spacer printing function (Optional)

Can bend aluminum spacer, Technoform, Alupro, Thermax, Swisspacer, and Stainless steel (Stainless steel optional)

Automatic drill glass filling hole (Optional)

| Item. | Spec. |

| Max. bending size | 2000mm*2000mm |

| Min. bending size | 250mm*200mm |

| Aluminum spacer width | 6A-27A |

| Dimension error | ±0.5mm |

| Angle error | ±1 |

| Air supply | ≥0.65Mpa |

| Total power | AC 220V/380V 50Hz 2.5Kw |

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After

shipment, we will send original documents to you by DHL which include

the packing list, commercial invoice, bill of landing, and other

certificates as required by clients.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close