Butyl Extruder Machine for Spreading Aluminum

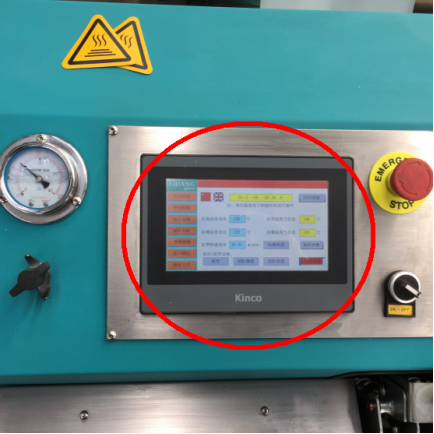

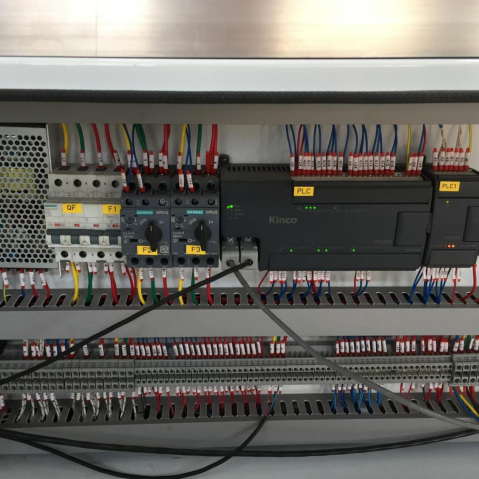

1. PLC control system, touch screen interface

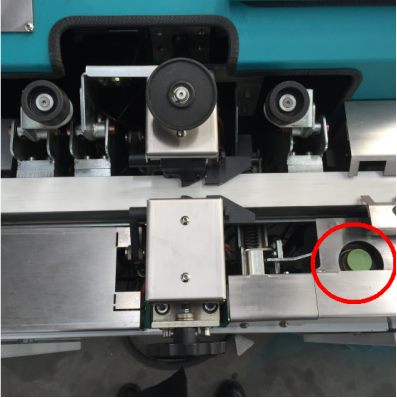

2. Automatically identify the width of aluminum bar, the glue nuzzle can be automatic adjust

3. The critical part of the hydraulic system using German imports of components to ensure that the plastic evenly full

4. Fast preheat, improve work efficiency

5. With preheating function

6. With exhaust inflatable function, improve the quality of sealing and save time for plastic

7. Quickly coating speed,can up to 47m/min

8. Saving the amount of glue

Price

$9.99

Product Details

Application

LJTB 01 Butyl extruder gadget is used for spreading aluminum spacer frames frivolously with warm soften butyl. The butyl extruder makes use of big electric manage panel which makes the operation greater less complicated than before. The conveyor of aluminum is managed through frequency converter. The pace may be adjusted from 0m/min to 47m/min, it's far the quickest pace in China till now. The butyl extruder may be very famous with energy-saving. Its squeezing machine adopts pneumatic and hydraulic supercharging machine, which makes the squeezing strain greater strong. The meting out cylinder adopts vertical rotary help machine, making the top off of butyl greater less complicated. The peak of compressing head may be adjusted robotically consistent with distinctive varieties of aluminum spacers. Finally, the butyl extruder has reached the global generation with the function of entire features and strong operating mode.

Equipment details

KINCO Touch Screen Clear interface, Simple operation, Smart touch screen,Updated programming. | Germany HAVE Valve Adopt Germany’s Harvey valve, more stable performance |

|  |

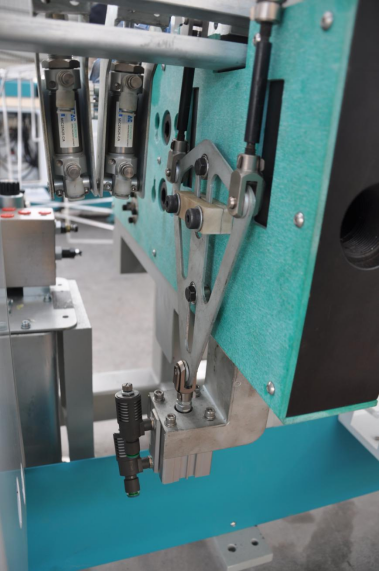

Alarm system Automatically alarm system, reminding adding butyl. | Germany Maximator Cylinder The supercharging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly. |

|  |

Germany Siemens parts Adopt Siemens brand, stable performance. | Glue cylinder Adopt the upright structure, easy to change butyl. |

|  |

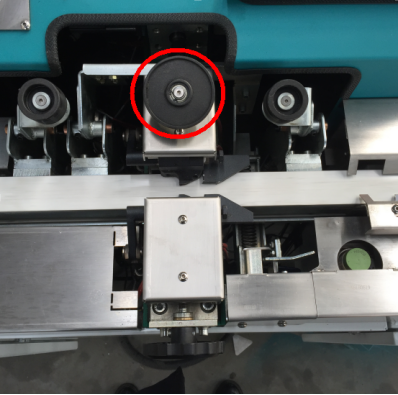

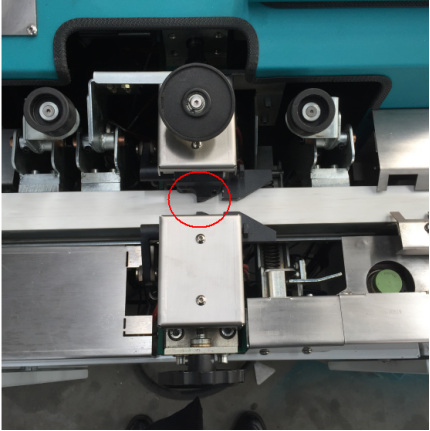

Guiding Wheel Using guiding wheel to help arc frames coating. | Sensor Automatically measure the width of frame, the distance of nozzle can be adjustable. |

|  |

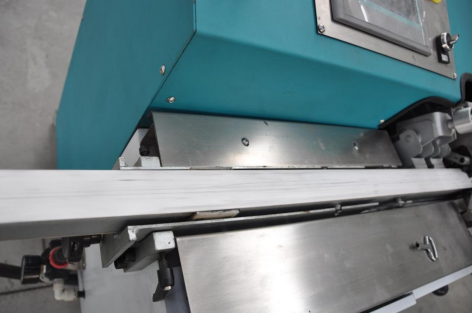

TEFLON glue nozzles Adopt Teflon glue nozzles, keep spreading quickly. | Special material Belt Using non-adhesive belt, keep clean. |

|  |

Special structure The special part controls both sides of nozzle opening and closing at the same time. | Auto-centering and auto-clamping. |

|  |

Crossbeam adjustable structure Crossbeam adjustable structure controls the spreading height. | Automatic filter function Automatically filter debris, keep spreading evently. |

|  |

Leading Technology:

Stable temperature device makes it convenient to adjust the sealing material automatically according to the changed coating speed.

The coating speed is up to 47m/min, save more than 40% butyl than others, only need 7g/m.

Quickly heating function, preheat the machines with only 20 minutes per day, improve work efficiency.

Technical Data

Squeeze pressure | 10-18MPa |

Temperature | 110~140℃ |

Aluminum spacer width | 4-30mm |

Speed | 0-47m/min |

Diameter of butyl cylinder | 200mm |

Air supply | 0.4m³/min |

Air pressure | ≥0.6MPa |

Total power | 415v 50 hz 3 phrase |

Dimension | 2800*700*900mm |

Weight | 750kg |

Main components

Name | Brand | Original |

PLC | KINCO | China |

Valve | HAWE | German |

Low voltage electrical apparatus | SIEMENS | German |

Frequency converter | KINCO | China |

Pneumatic component(cylinder/valve) | ARTAC | Taiwan |

Quick exhaust valve/Vacuum generator | SMC | Japan SMC |

Travel light | OMRON | Japan |

Optical fiber | OMRON | Japan |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close