Glass sealing robot in China

1. Germany Siemens PLC control system, touch screen interface

2. Automatic identification of coated and Low-E glass

3. 3 pairs of soft brushes can wash online and offline Low-E glass

4. The washing machine adopts SS material and waterproof device

5. Water tank with automatic temperature control and water washing system

Price

$68,000.00

Product Details

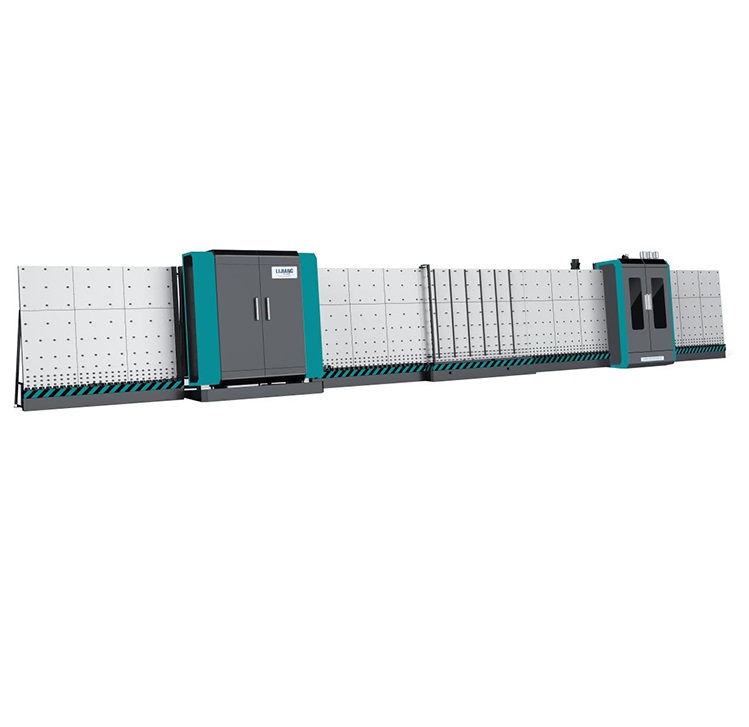

Insulating Glass sealing robot

Transfer section

Coating detection mechanism, automatic detection of offline Low-e film

Washing machine

1. Using 6 pieces of soft brushes with 0.lmm soft hair. can wash low- glass

2. New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife

3. The air knife can automatically adjust the width of the air knife according to the thickness

4. The operation box with washing speed display, can accurately display washing speed

5. Water tank automatic temperature control, water replenishing system

6. European silencer system

7. Stainless steel material

Discharge section

Storage glass

Inspection and installation section

The new structure of this section is changed to an inline beam lifting structure (double beam). It is easy to inspect and wipe the glass

Transfer section

Automatic measurement of glass thickness. It can be used according to actual needs when working

Pressing and filling section

Main feature:

8. Adopts conveyor belt to transfer glass, uses servo motor to press glass.

9. The pressing plate can be opened for easy maintenance

10. Pressing board with adjustable structure to guarantee long-lasting service life

11. Automatically fill argon gas with significant sealing effect. higher argon content

12. Set zones to fill different size of olass with follow-up sealing method reduces argon loss

13. Can set gas value and show the process of filling aas on the touch screen

Ø Fast reacting sensor for permanent control of gas filling process

Ø Gas concentration can reach more than 90%.

Ø No need to drill holes on the spacer frame

Ø Standard gas is Argon gas

07 discharge section

Storage glass

Can be connected to sealing machine

Unit | LJBZ3370 | |

Voltage | 380V 50HZ3P | |

Total power | KW | 545 |

Washing speed | m/min | 2-10 |

Maximum working speed | m/min | 45 |

Minimum glass size | mm | 450*280 |

Maximum glass size | mm | 3300*7000 (single press model) 3000*3000 (double press model) |

Flat glass thickness | mm | 3-30 |

Washing brushes | Pieces | 6 |

Maximum thickness of insulating glass | mm | 80 |

Total gas consumption | L/min | 1500 |

Conveyer roll height | mm | 520 |

Dimension (L*W*H) | mm | 47200,3500,4500 |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close