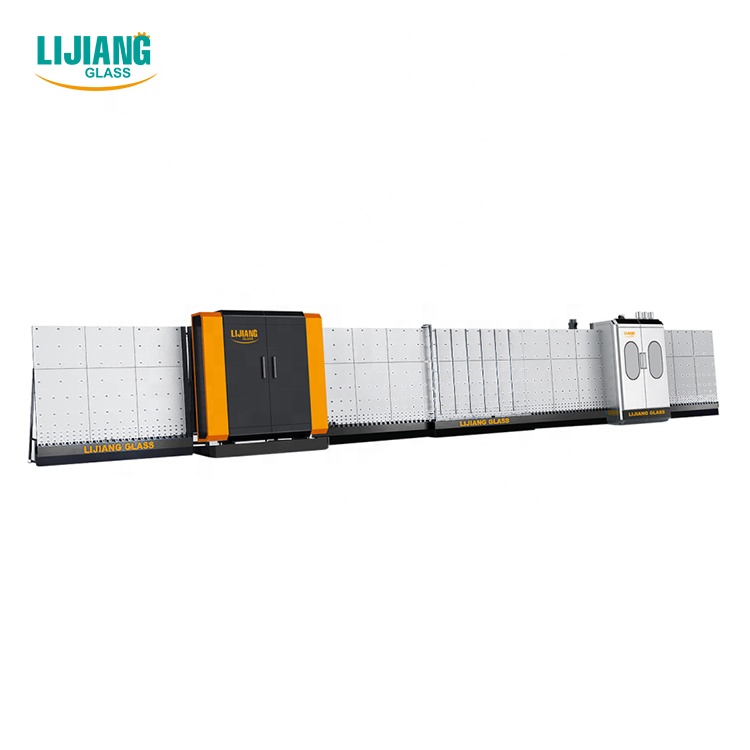

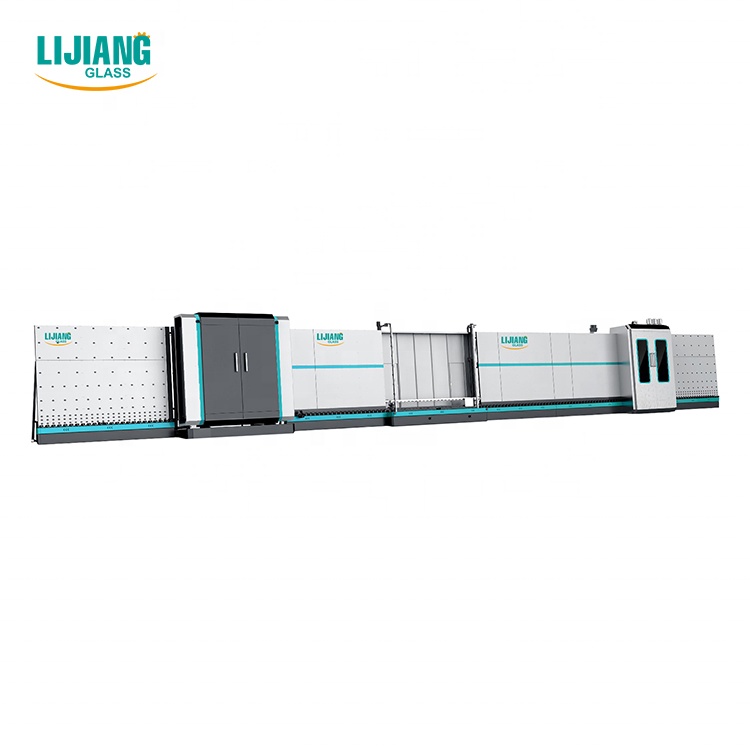

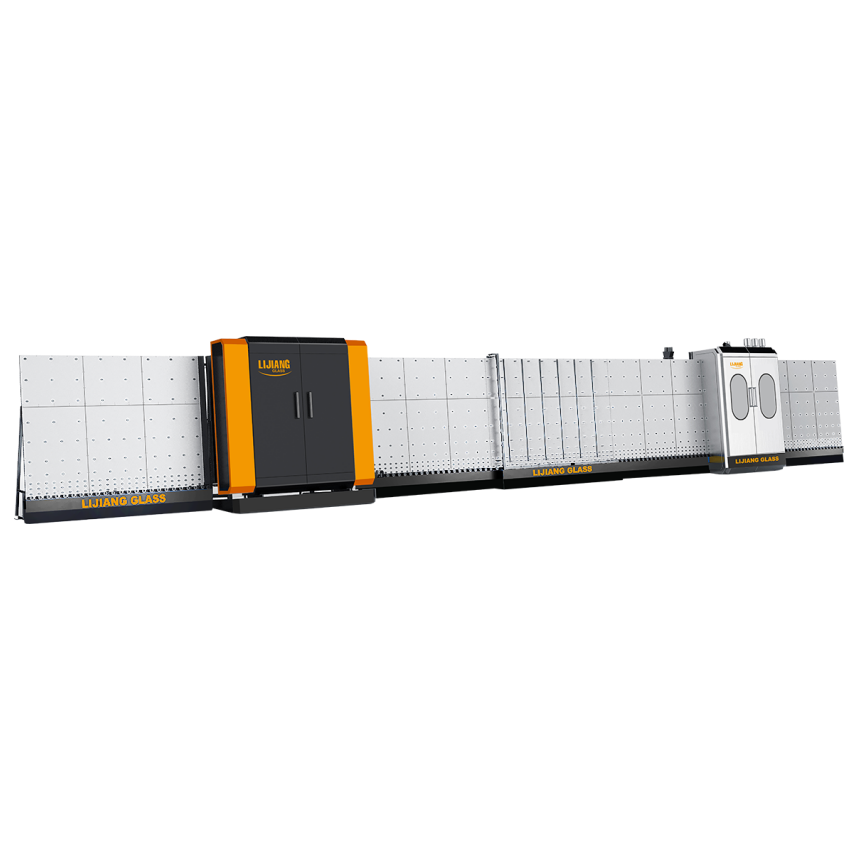

Super Automatic Vertical Insulating Glass Production Line

Easy operation mode

Faster processing speeds than its counterpart

A perfect after-sales system

A worry-free experience after the purchase

Low failure rate

Price

$90,000.00

Product Details

Automatic vertical insulating glass production line is suitable for glass deep processing

Products introduction

The whole Insulating glass production line LJBZ2535 has 7 parts :01 transmission sections; 02 Cleaning and drying section; 03 transmission segment; 04 Check the installation section. 05 transmission segment; 06 plate pressure filling argon section; 07 discharge section. Optional Functions: •Step glass with optional edges •Shaped glass •Filling argon gas automatically •Air-floating technology to transfer glass •PLC control system, touch screen interface •Using Siemens servo motors •Applicable to produce double glass, triple glass To prevent the glass from being contaminated by wheels and leaving traces to improve the IG production’s high quality.

Main Technical Parameter

Item. | Spec. |

Max.glass size | 2500mm*4500mm |

Min.glass size | 280mm*400mm |

Glass thickness | 3-15mm / 19mm |

Insulating glass thickness | 50mm / 60mm |

Glass washing speed | 2-10m/min |

Glass conveyor speed | 45m/min |

Washing brushes | 3 pairs |

Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

Air supply | Flow: 0.8m/min |

Air pressure | ≥0.8MPa |

Total power | 3P 380V 50HZ 40KW |

Dimension | 23500*3500*3700mm |

Weight | 6500kgs |

Name | Brand |

Servo motor | Germany Simens |

Servo driver | Germany Simens |

Servo motor | Germany Simens |

Servo motor | Germany Simens |

PLC | Germany Simens |

Low voltage component | Germany Simens |

Frequency converter | Germany Simens |

Switching power supply | Taiwan MW |

Optoelectronic switch | Korea Autonics |

Pneumatic component | Taiwan Airtac |

Pneumatic component | Taiwan Airtac |

Touch screen | Taiwan Wenview |

Travel switch | Taiwan (TEND) |

Relay | Japan Omron |

Button and indicator light | French Schneider |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close