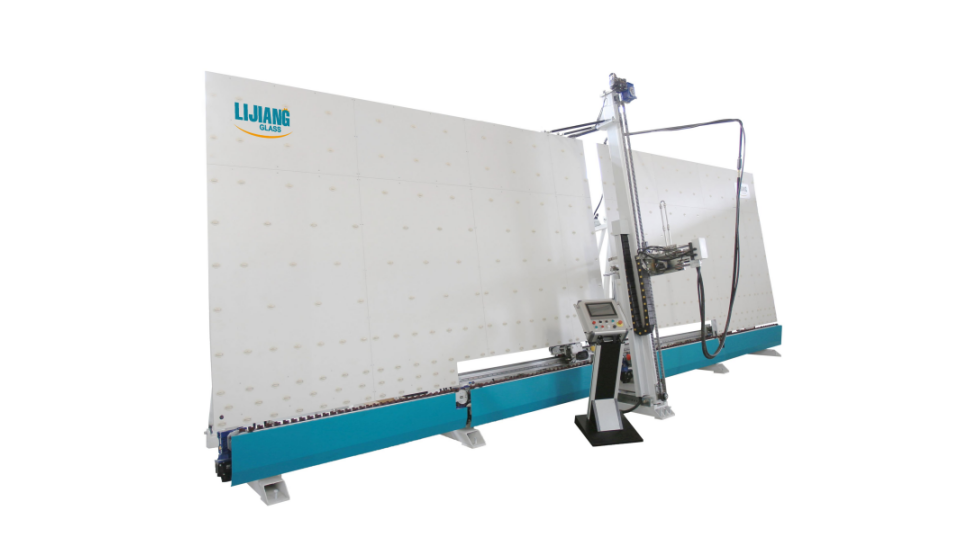

Vertical Insulating Glass Sealing Robot

1. Japan Yaskawa servo control system, full automatic and high-efficiency

2. Automatic memory function, no need to input parameters repeatedly

3. Automatically repair glass corners with scraper and roller

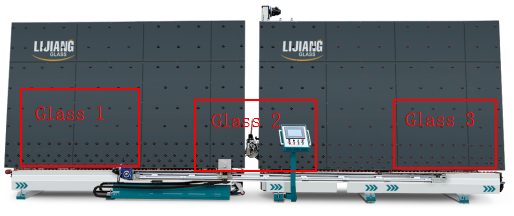

4. Machine has four sections, can store glass

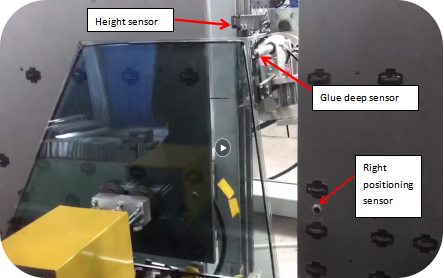

5. Automatically measure glass size and glue depth, adjust sealing speed

6. Adopt timing belt, smooth transfer and accurate position

Price

$9.99

Product Details

Application

Min & max glass sizes can be optional

Adopt eight servo motors

Adopt japan anchuan servo manipulate gadget with strong overall performance

Routinely degree glass length, glue intensity and glue velocity with linear adjustment

Adopt timing belt to maintain clean carry with correct position

Spares are produced with high standardization and excessive precision, make sure the machine may be used with long-term operating

The glass corners are full without air bubbles, smooth surface, no need to

Full automatic and high-efficiency machine

New scraper design, especially for making train IG with very even sides and corners, without any bubbles.

Automatically repair glass corners with beautiful surface

Smooth convey without scratch and pollution

Single-function parts are equipped with manual functions, easy adjustment

Shaped IG units (Optional)

Stepped IG units with four sides (Optional)

Double and Triple IG units

Detail Images

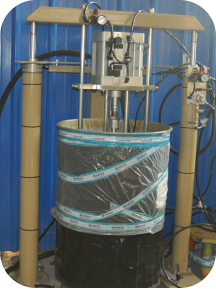

One Set of Pump A & Pump B

Equipped with single A component and single B component. Glue A and B automatic mixing, automatic ratio.

Pump A | Pump B |

|

|

Two Sets of Pump A & Pump B

Equipped with two sets of A components and two sets of B components, which can be used for two kinds of different sealants, such as silicone rubber, polysulfide rubber, silicone structural adhesive and so on.

Pump B | Pump A |

|

|

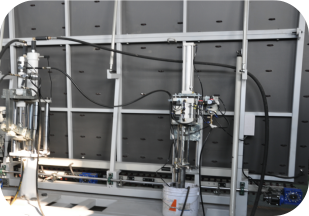

Back Glue Device | Two Suckers Device |

When the pressure increasing, more Glue B will flow back automatically, saving materials. | Adopting two suckers for preventing to move glass during sealing. |

|

|

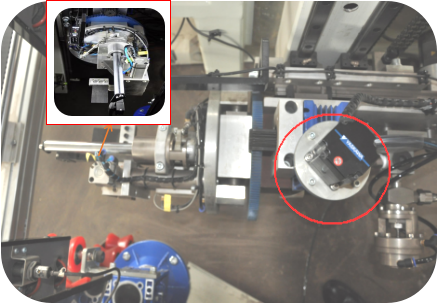

The Device of Sealing Part | Dyad Body Device |

Adopt Japan YASKAWA servo motor to control the sealing part with 360°rotating. Setting scraper blade to scrape out extra glue and no need to repair glass corners by second time. | The dyad body device has two functions. The left one is used for filtering impurities and moisture when filling gas into , then the right one plays the role of lubrication. |

|

|

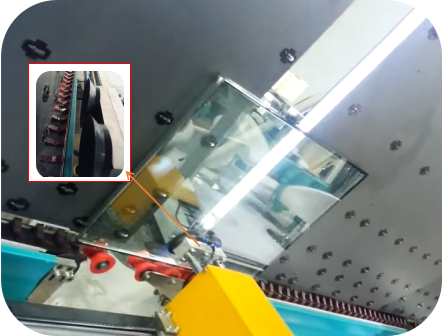

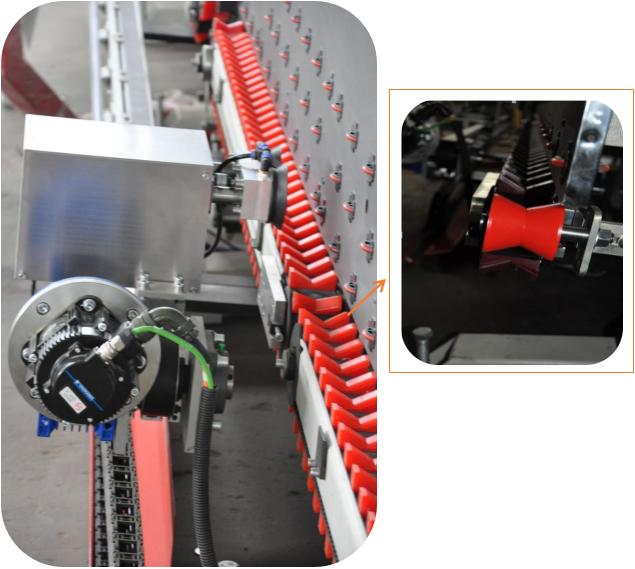

Timing belt | Intelligent Sensor |

The time belt device ensure that glass can be smooth transmission and positioned accurately. | Automatically position the glass and sensor glue deep, the coating speed can be adjustable online. |

|

|

Storage Function | Eight Servos |

It can store three pieces of insulating glasses when glass sizes are less than 1.8m. | The robot uses eight YASKAWA servos, four of them control transmission parts, in the another four servos, they control sucker, lifting, driving and revering mechanism and rotating. |

|

|

Main electrical components

The main electrical components are adopted Siemens, SMC and so on famous spares to maintain more stable performance.

Technical data

Max.glass size | 2500*4000mm |

Min.glass size | 400*300mm |

Glass thickness | 12-56mm |

Working speed | 5-40m/min |

Air pressure | 0.6-0.8MPa |

Squeeze pressure | <35MPa |

Plane angle | 6°- 9° |

Max glass weight | 400kg |

Voltage power | 380V 15kw |

Overall dimension | 8700mm*2500mm*3500mm |

Main components list

Name | Brand |

Switch | SIEMENS |

Servo motor | Japan YASKAWA |

I/O model | Japan MSYSTEM |

Lower voltage component | Siemens |

CPU | Japan YASKAWA |

Frequency converter | Japan OMRON |

Switching power supply | Taiwan MW |

Pneumatic component | Japan SMC |

PLC | Siemens |

Guideway | Siemens |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close