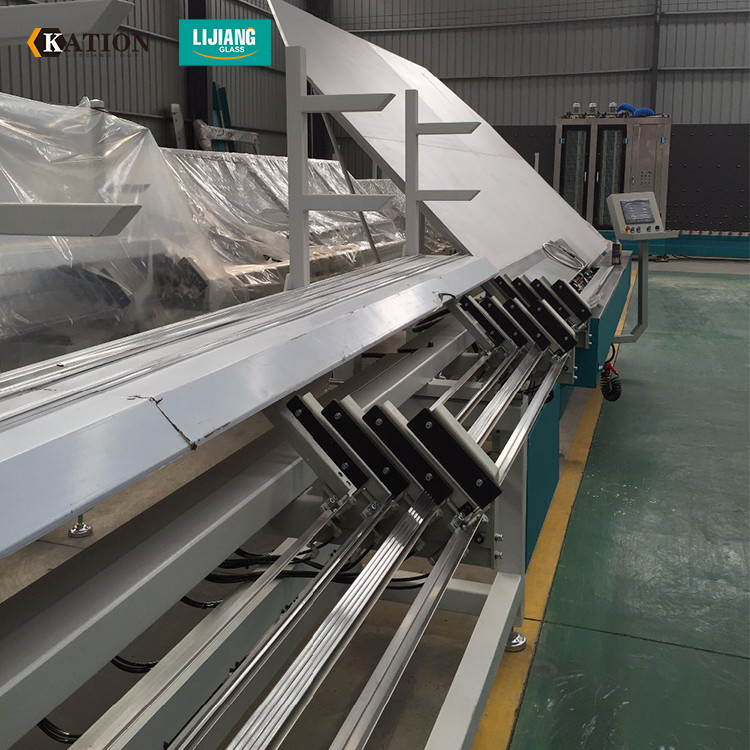

aluminum spacer bending machine

Adopt Siemens PLC control system

There are 4 Siemens servo

Adopt 4 sets of racks which could storage more different sizes of spacers. Use Siemens servo to change different racks.

Automatically cut and feed aluminum spacers

Bend shaped spacer frames continuously

Automatically avoid the connecting corner while bending and cutting

The machine grabs the spacer from the top instead of grabbing the spacer from bottom, solving the old-fashioned reversing problem.

Using industrial computer technology which could realize the on-site drawing by workers on the industrial computer and directly bending the drawn graphics.

The special machine hand device is used to bend big spacer frame

Price

$22,000.00

Product Details

Application

Automatic spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better.

Main Feature

• Siemens 1200 PLC control system, fast working speed, high efficiency

•4 groups of aluminum strip storage (optional 2 or 12 groups of storage)

• Automatic cutting and transfer of aluminum gaskets

• Automatic dowel avoidance when bending and cutting

• Continuous bending of aluminum spacer strips

Aluminum gaskets are 6A-27A in size

• Can bend aluminum gasket, stainless steel gasket

• Connect to ERP system (optional)

•USB input function, directly read excel format files

• Automatic drilling and argon filling (optional)

• Space bar print code function (optional)

• Curved shaped frames. Use a round wheel device to bend round frames or boxes with rounded corners. Minimum R60, maximum R150, interval size: 6A-16A). Different sizes of aluminum strips require different sizes of tools (optional)

Detailed introduction:

• Space bar print code function (optional)

•2 or 12 groups of storage (optional)

• Print label adhesive

• Stainless steel bending (optional)

• Use a round wheel device to bend round frames or rounded corners. Minimum R60, maximum R150, interval size: 6A-16A (optional)

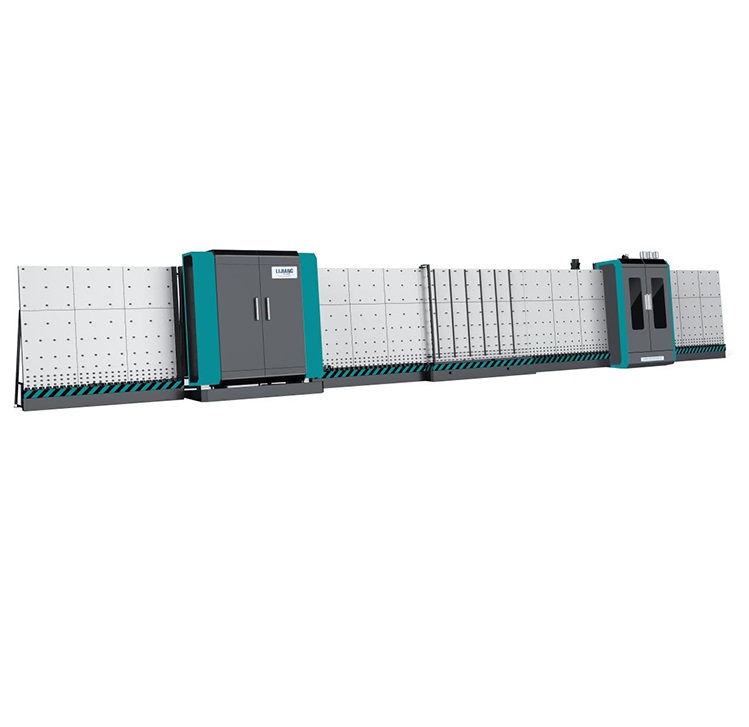

Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

Min.bending size | 250mm*200mm |

Aluminum spacer width | 5.5-27mm |

Dimensional error | ±0.5mm |

Angle error | ±1º |

Processing speed | ≤26s |

Air supply | ≥0.65MPa |

Total power | AC220/380V 50Hz 2.5KW |

Dimension | 10500mm*2200mm*2600mm |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close