Automatic Glass Washing Machine

1.Horizontal structure, simple operation. The machine frame adopts heavy thickness aluminum alloy to avoid to be out of shape when working for a longtime.

2.With stainless steel water sink and high pressure pre-spraying (high pressure pump) in loading ( in-feed), the rubber roller can pre-wash automatically to clean out the glass powder or scraps.

Price

$9.90

Product Details

Automatic Glass Washing Machine

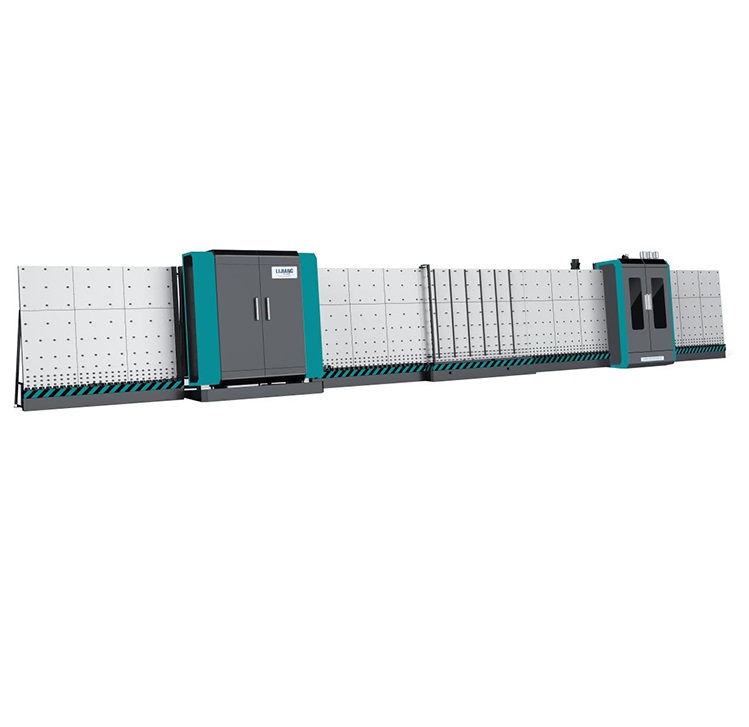

General description of Automatic Glass Washing Machine

Automatic Glass Washing Machine consists of in-feed, prewash, washing&drying, out-feed section. To make good washing performance and quick air dry, it adopts 3 pairs brushes and 2 pairs air knives with 1pc air blower. It fits for tempered glass, solar glass, laminated glass, Low-e glass or any other flat glass processing.

Parameter of Glass Washing Machine

Parameter |

Max. Width: 2000mm |

Min. Size:400×400mm |

Glass thickness:3~28mm |

Working table height:900mm±30mm |

Blower power: 18.5kw |

Total power: 28kw |

Weight: 3000kg |

Dimension: 5700×2800×2500mm |

Low-e brush: 2pcs,dia 0.15mm, Hard brush: 4pcs, dia 0.25mm |

Water heater: 1pc of 3KW |

Brush roller dia: 160mm |

Rubber roller dia: 75mm |

Processing Speed:0.5~12m/min |

Characteristics of Glass Washing Machine

1.Horizontal structure, simple operation. The machine frame adopts heavy thickness aluminum alloy to avoid to be out of shape when working for a longtime.

2.With stainless steel water sink and high pressure pre-spraying (high pressure pump) in loading ( in-feed), the rubber roller can pre-wash automatically to clean out the glass powder or scraps.

3.Blower: Low noise and vibration.

4.Conveying adopts frequent converter, digital display and convenient operation, which do good to connect with double edging line, hollow glass line, safety glass line, etc. Table rollers adapt superior rubber and transmitted by gear wheel which makes a stable working.

5.Side covers and tanks and any other water touched material adopt stainless steel 201.

6.Washing and Drying section can be lifted to Max. 400MM by adjustment on electrical board with 4 legs(corners) increasing through motors and encoder.

7.Air knives adopt advanced technique device, large power and quick air dry.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close