LIJIANG Automatic aluminum spacer bending machine

1.Siemens PLC control system

2.Automatic cutting and feeding spacers

3.Automatic framing of large size aluminum frame

4.Automatically avoid the pins

Price

$25,000.00

Product Details

1. What is the role of aluminum strip bending machine? Why do aluminum bars bend?

Aluminum strip bending machine is mainly used for continuous bending of insulating glass aluminum strip. Aluminum strip bending can improve the sealing performance of insulating glass and its appearance is better

2. What kinds of rigid insulating glass spacer are there? Can lijiang hollow equipment be bent?

Hollow glass rigid spacer is divided into aluminum strip, stainless steel strip, stainless steel composite warm edge strip, and glass fiber strip, Lijiang hollow glass bending machine can fold aluminum strip and stainless steel composite warm edge strip

3. The length of aluminum strip is not enough in the bending process. Can the aluminum strip be connected automatically?

Lijiang aluminum strip bending machine can be connected automatically

4. Can the equipment of Lijiang aluminum strip bending machine fold abnormals?

Aluminum bar bending function is shaped, mainly octagon, hexagon, trigonal, circular and so on

5. Which brands are used for PLC and servo motor driver of Lijiang Aluminum strip bending machine?

The PLC and servo motor driver of aluminum strip bending machine is Siemens from Germany

6. Does lijiang aluminum strip bending function print labels? What are the main functions?

Aluminum strip bending machine with printing label function, mainly scattered single home decoration single aluminum frame size better distinguish

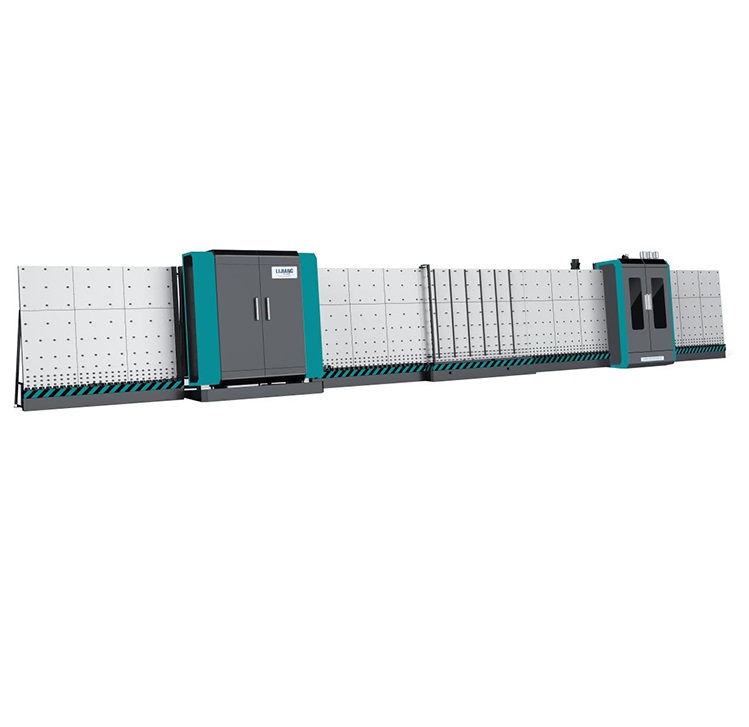

Automatic aluminum spacer bending machine is controlled by PLC. By virtue of the mode of human-machine interactive data input on the touch screen, the facility can get the expected parameter data in different specifications of rectangular aluminum frames, or the convex polygon’s edge and corner data composed of arc-shaped section or straight flange not more than 8 edges. Simultaneously, acquire the quantity of the aluminum frames that are required to be processed, as well as the parameter of other control equipment in accurate operation, which essentially satisfy the required shapes of the current insulating glass.

Dimension (L X W X H) | 10500 mm X 2200 mm X 2600 mm |

Air Source (MP) | 0.65 |

Power Supply and Consumption | AC-380V 50HZ 2.5 kw |

Size of Aluminum spacers | W: 6-24 mm L: 4000 – 6000 mm |

Size of Processed Aluminum Frames | Min: 150 X 250 mm Max: 2000 X 2000 mm |

Processing Speed | < 25 s / pcs (1000 mm X 1000 mm) |

Processing Database | 4 specifications with 48 sizes of aluminum frames can be set up at the same time. Maximum quantity for continuous processing reaches up to 9,999 pcs. |

Weight | 1255 KG |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close