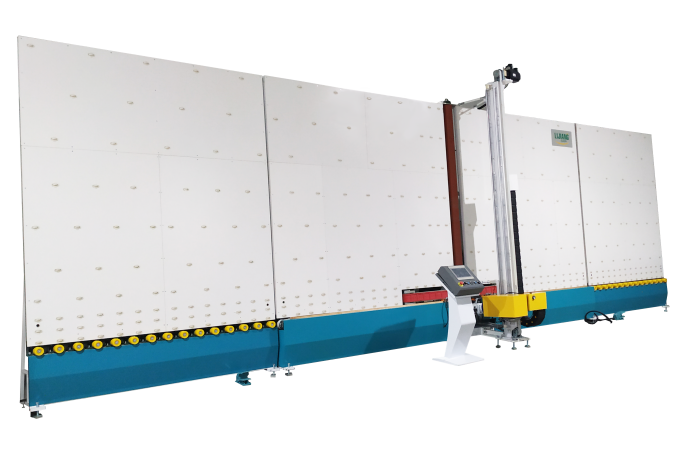

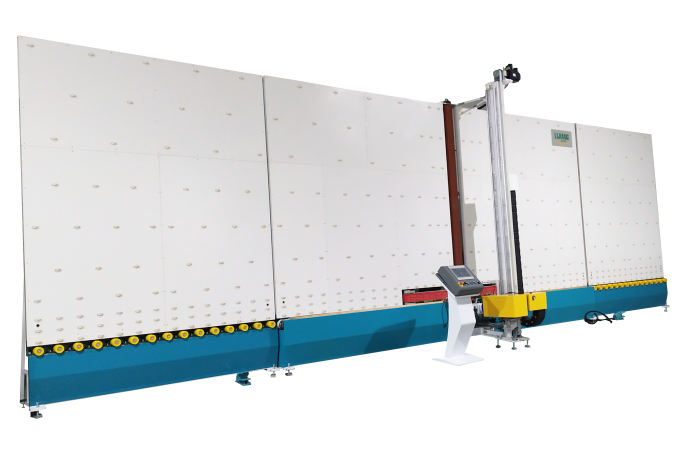

Vertical Low-E Deleting Machine

1.Two-way glass access

2. Automatically measure size

3.Automatically distinguish low-e surface

4.Edge deletion is adjustable

5.PLC control system, touch screen interface

Price

$40,000.00

Product Details

1. Vertical Edge Deleting Machine Usage

vertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system. The device has a small footprint, high efficiency, reliable performance and easy maintenance.

2.Low-E Deleting Machine Parameters

Power Supply | Voltage(V) | 380V |

Hertz(Hz) | 50 | |

Total Power | Kw | 3.35 |

Transmission speed | m/min | 2~29 |

Edge finish speed | m/min | 2~29 |

Glass thickness | Mm | 3~19 |

Edge finish width | Mm | 10~150 |

Diameter of grinding wheel | Mm | 200 |

Width of grinding wheel | Mm | 10,12,15 |

Grinding wheel speed | r/min | 0~3000 |

The smallest glass size | Mm | 350×500 |

The largest glass size | Mm | 2500×4500 |

Height of conveyor roller | Mm | 500 |

Total air consumption | L/ min | 100 |

Total weight | Kg | ≈3700 |

Dimensions | L×W×H(mm) | 8000×2500×3400 |

3. Main Technologies Instruction

A. The machine uses Delta control system and servo motor, which provide stable operation and high positioning accuracy. Large size true color touch screen is very simple and easy to operate.

B. The whole machine has two modes of operation, automatic and manual. Each section can be used as a separate manual machine which is more convenient and simple.

C. The Vertical Edge Deleting Machine LJCM2545 includes in-feed conveyor, edge deleting assembly and output conveyor.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close