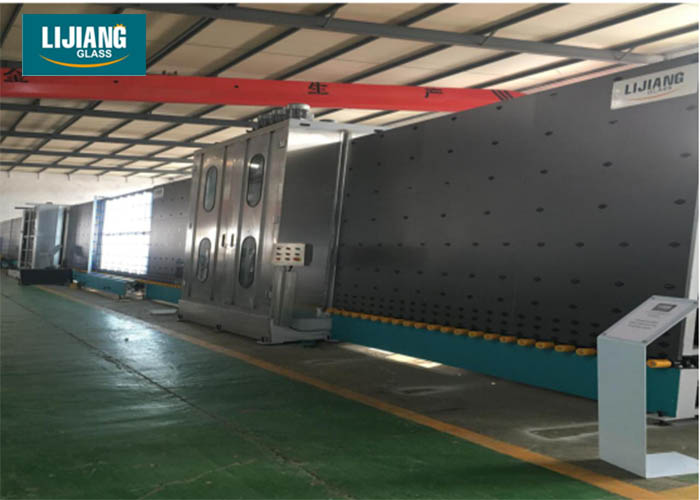

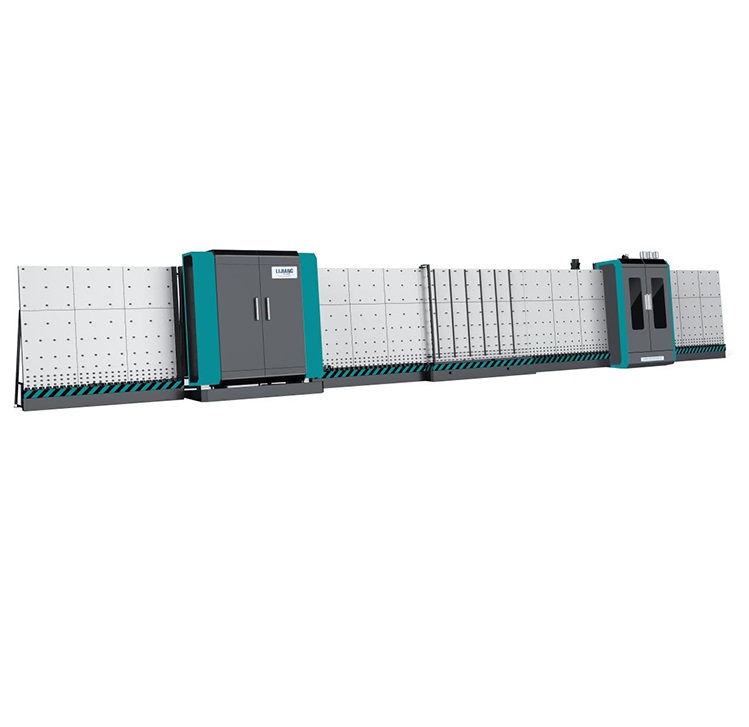

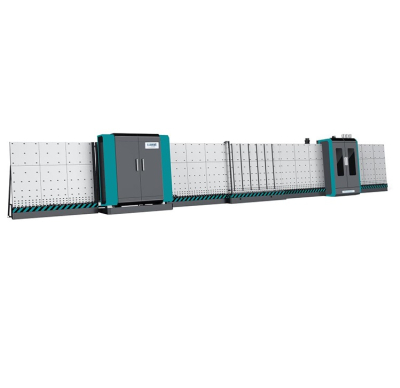

Complete Automatic IG Production Line for Window and Doors

1. Adjustable Pressing Parts

2. Air-support conveyors (optional function)

3. Electricity components - Germany simens/ japan yaskava

Product Details

1, Loading part

To Avoid the low-e Glass put inverse side and Leave wheel marks or scratch low-e Coating We use coating inspection -metal film conductive (other company use Photoelectric detection, hard to recognize for higher transparent film coating)

(Nylon and Polyurethane + metal column)

2, Washing and Drying part

* 3 pairs of soft brush can clean low-e glass and ordinary glass, soft hair diameter less than 0.1mm.

* Stainless steel, rust proof.

* The air knife is float design, and the appropriate distance between the glass surface and the air knife is always 3mm (Note :3mm is the best drying distance).

3, Detecting part

4, Assembly part

Built-in beam lifting structure (double beams)

Convenient for detect and wipe the glass

5 Adjustable Pressing Parts

In order to avoid deformation problems in the welding of the holder (the machine cannot press DGU correctly, evenly and tightly), our solutions are as follows:

a. we all do the aging treatment , it’s the stress-remove by vibration failure device.

b. The important is We design the 74 points on the backbord, if there have any out-of shape problems we can adjust easily at any time. ( same like Bystronic structure )

6 Electricity components

We are using Germany simens/ japan yaskava

Main components list

Components | Brand | Remark |

Servo motor | Germany Simens | For stepped glass |

Servo driver | Germany Simens | For stepped glass |

Servo motor | Germany Simens | For transfer |

Servo motor | Germany Simens | For press |

PLC | Germany Simens | |

Low voltage component | Germany Simens | |

Frequency converter | Germany Simens | |

Switching power supply | Taiwan MW | |

Optoelectronic switch | Korea Autonics | |

Pneumatic component | Taiwan Airtac | |

Pneumatic component | Taiwan Airtac | |

Touch screen | Taiwan Wenview | |

Travel switch | Taiwan (TEND) | |

Relay | Japan Omron | |

Button and indicator light | French Schneider |

Technical data

2000*2500 Max.glass size

| Normal glass | 2000*2500mm

|

Glass with argon gas | 2000*2500mm | |

2500*3500 Max glass size | Normal glass | 2500*3500mm |

Glass with argon gas | 2500*3200mm | |

Min.glass size | 280*450mm | |

Glass thickness | 3-15mm | |

Insulating glass thickness | 50mm(special made for 60mm need special notice) | |

Glass washing speed | Summer 8-10m/min winter 6-7m/min | |

Glass conveyor speed: | 45m/min | |

Washing brushes | 3 pairs | |

Water supply: | Water consumption:0.5t/h conductivity:≤50μs/cm6-7 | |

Air supply | Flow: 0.8m/min | |

Air pressure | ≥0.8MPa | |

Total power | 3P380V 50HZ 34KW | |

Dimension | 23500*3500*3700mm | |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close