Glass Double glazed glass equipment in China

1、Adopt SIEMENS control system, keep stable performance

2、PLC control system, touch screen interface

3、Automatically adjust the depth of glue with digital display

4、Using servo to control system, modular function, superposition function

5、Applicable to produce stepped IG, triple IG and shaped IG

6、Two pieces of IGU can be made and filled with argon gas in one time (Optional)

7、Min & Max glass sizes can be optional

8、Using 6 pieces of soft brushes

9、Wash online and offline low-e glass, automatically recognizes Low-e film

10、Washing part adopts the design of upper and lower layered structure

11、Adopt variable frequency fan, energy efficient, good cleaning effect

12、The air knife can automatically adjust the width of the air knife according to the thickness

13、Using intelligent intermittent energy-saving working methods

14、Hierarchical type washing system

15、Water tank automatic temperature control, water replenishing system

16、European silencer system

17、304 stainless steel materials

Price

$65,000.00

Product Details

Automatic insulating glass Production Line LJZK2535

LIJIANG IG line adopts the latest technology, its main purpose is to create high-end quality and provide a great deal of useful functionality, improve production efficiency, save production costs and produce maximum benefits.

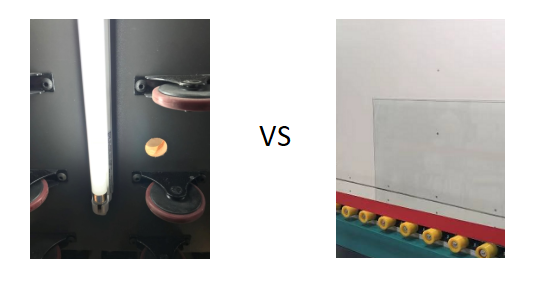

Now LIJIANG mainly has two kinds of IG line with different two different technologies. One (Picture 1) uses transfer wheels to transport glass, and the other (Picture 2) is a new technology that uses air-floating technology to transport glass. This new technology is to prevent the glass from being contaminated by wheels and leaving traces, so new technology is used to improve the IG production’s high quality. The front and back transfer wheel are all moved, all actively transferred. It can guarantee the big and thick glass pass through smoothly.

The new air – floating technology uses air to support glass and transfer glass. When glass is washed clearly from the washing machine, using air to transport the glass, it won't be contaminated. Ensure that the produced insulating glass is of the highest quality.

As different countries have different water quality, in order to ensure that the glass is washes clearly enough, adopting air heating system, to use soft water to wash glass. What’s more, using water filter system to make water recycling, save water and keep the water clear.

Technical data

Max. glass size | 2500mm*3500mm |

Min. glass size | 280mm*400mm |

Glass thickness | 3-15mm |

Insulating glass thickness | 50mm / 60mm |

Glass washing speed | 2-10m/min |

Glass conveyor speed | 45m/min |

Washing brushes | 3 pairs |

Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

Air supply | Flow: 0.8m/min |

Air pressure | ≥0.8MPa |

Total power | 3P 380V 50HZ 40KW |

Dimension | 23500*3500*3700mm |

Weight | 6500kg |

Electrical parameters

NAME | ORIGIN | BRAND |

Transfer motor | Germany | SIEMENS |

Brush motor | Germany | SIEMENS |

Servo motor | Germany | SIEMENS |

PLC | Germany | SIEMENS |

Low voltage electrical appliance | Germany | SIEMENS |

Frequency converter | Germany | SIEMENS |

Micro Switch | Taiwan | TEND |

Button and indicator light | France | SCHNEIDER |

Touch screen | Taiwan | WEINVIEW |

Intermediate relay | Japan | OMRON |

Water pump | China | LINGXIAO |

Guide | Taiwan | HIWIN |

Pneumatic Components | Taiwan | AIRTAC |

Electric gauge | China | MIRAN |

Photoelectric switch | Korea | AUTONICS |

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD | ||

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close