Insulating glass unit production machinery IGU line made in China

1.3 pairs of soft brushes can wash online and offline Low-E glass.

2.The washing machine adopts stainless steel material and waterproof device.

Price

$210,000.00

Product Details

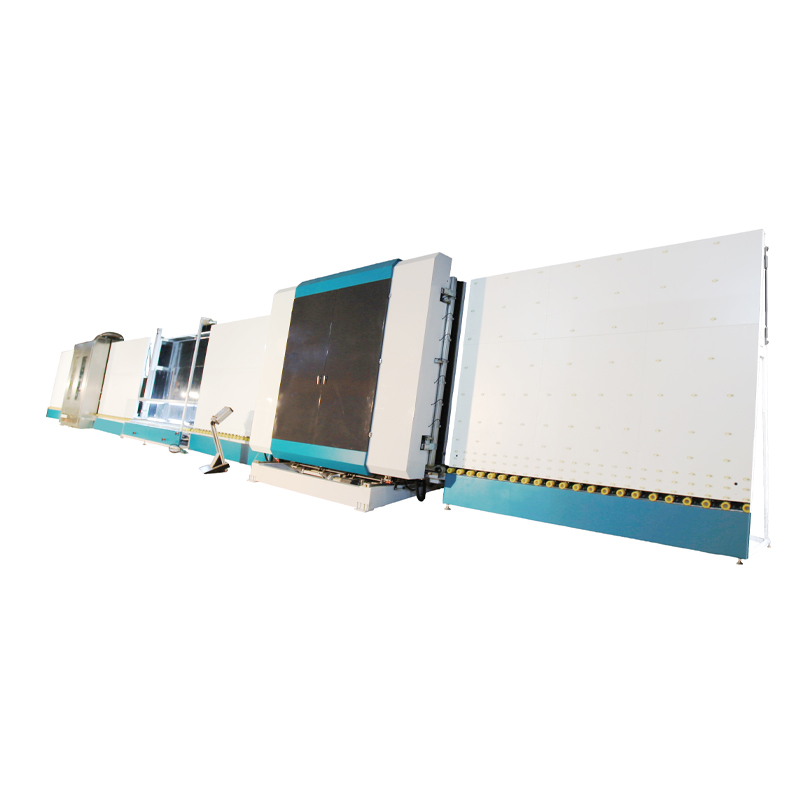

AUTOMATIC GLASS WASHING AND COMBINING LINE WITH HYDRAULIC PANEL PRESS 3300*7000 mm

Automatic glass washing and combining line with hydraulic panel press can assemble and press double, triple or structural (step, facade) insulating glass units.

Model of Standard line: LJZB3370

PERFORMANCE:

1.The whole line use Germany Siemens PLC control system,touch screen interface,Easy and convenient operation .

2.In the first section you can see the sensor , It can detect the film of Low-e glass.(At the same time, it can also automatically measure the thickness of the glass )15-30 mm.

3.3 pairs of soft brushes can wash online and offline Low-E glass.

4.The washing machine adopts stainless steel material and waterproof device.

5.Water tank with heating function .

6.Air heating system

7.Washing speed display on the screen interface.Max washing speed can reach 10 meters/min.

8.There are many adjustment points on plate board .it can keep the plate pressing surface straight.

This is a very important detail. If it can’t be adjusted after deformation, it is easy to crush the glass.

9.Double glass ,triple glass,shaped glass are available .

Optional function :

1.Pre-washing

2.Air-floating convey

3.Step glass

4.Gas filling

Filling gas from the bottom of the synchronous belt, the air hole is always between the first glass and the aluminum frame, so that keep high gas concentration, uniform, fast speed, saving air source.

Display the process of filling online with high gas concentration .

In China , there are many factory can’t display the process on filling online , it only set up the time of filling ,it can not ensure the gas effect.

Details introduce of the LJBZ3370

01 transfer section

Coating detection mechanism, automatic detection of offline Low-e film

The Inlet Conveyor is a loading zone conveyor that is designed to load glass sheets into the washing machine. Thanks to loading support legs the big sized glasses can be loaded easily. With its modular infrastructure our machine is ready to extensions with optional conveyors for jumbo glass washing.

02 washing machine

Main feature:

• Using 6 pieces of soft brushes with 0.1mm soft hair, can wash low-e glass

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• Water tank automatic temperature control, water replenishing system

• European silencer system

• Stainless steel material

It is designed to wash the glass sheets with high quality washing brushes at maximum quality and to reliably dry the glasses with specially designed fans. With our glass washing machine we offer you maximum sensitivity and quality for glass washing. Vibration free working thanks to heavy and robust steel construction structure.

• 03 discharge section

• Storage glass

• 04 inspection and installation section

The new structure of this section is changed to an inline beam lifting structure (double beam). It is easy to inspect and wipe the glass

• 05 transfer section

• Automatic measurement of glass thickness. It can be used according to actual needs when working.

• 06 pressing and filling section

Main feature:

• Ultra-long (2500mm*3500mm) insulating glass can be compressed

• Adopts conveyor belt to transfer glass, uses servo motor to press glass

• The pressing plate can be opened for easy maintenance

• Pressing board with adjustable structure to guarantee long-lasting service life

• Automatically fill argon gas with significant sealing effect, higher argon content

• Set zones to fill different size of glass with follow-up sealing method reduces argon loss

• Can set gas value and show the process of filling gas on the touch screen

• Fast reacting sensor for permanent control of gas filling process

• Gas concentration can reach more than 90%

• No need to drill holes on the spacer frame

• Standard gas is Argon gas

• 07 discharge section

• Storage glass

• Can be connected to sealing machine

Technical data

Max. glass size | 2500mm*4500mm (Secondary plate pressing and auxiliary sucker mechanism) |

Max glass size for filling gas | 2500mm*3500mm |

Min. glass size | 280mm*450mm |

Glass thickness | 3-15mm |

Insulating glass thickness | 60mm |

Glass washing speed | 2-10m/min |

Glass conveyor speed | 45m/min |

Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

Air supply | Flow: 1500L/min |

Air pressure | ≥0.8MPa |

Total power | 3P 380V 50HZ 40KW |

Dimension | 23500*3500*3700mm |

Weight | 8500kg |

Electrical parameters

NAME | ORIGIN | BRAND |

PLC | Germany | SIEMENS |

Low voltage electrical appliance | Germany | SIEMENS |

Frequency converter | Germany | SIEMENS |

Servo motor for step glass | Japan | FUJI |

Photoelectric switch | Germany | SICK |

Micro Switch | Taiwan | TEND |

Button and indicator light | France | SCHNEIDER |

Touch screen | Taiwan | WEINVIEW |

Intermediate relay | Japan | OMRON |

Brush motor | China | QINGHUA |

Water pump | China | LINGXIAO |

Guide | Taiwan | HIWIN |

Pneumatic Components | Taiwan | AIRTAC |

IG line without filling gas online | ||

NAME | ORIGIN | BRAND |

Servo motor | Germany | SIEMENS |

PLC | Germany | SIEMENS |

Low voltage electrical appliance | Germany | SIEMENS |

Frequency converter | Germany | SIEMENS |

Transfer motor | Taiwan | LINHAI |

Brush motor | Taiwan | LINHAI |

Water pump | China | LINGXIAO |

Guide | Taiwan | HIWIN |

Pneumatic Components | Taiwan | AIRTAC |

Electric gauge | China | MIRAN |

Photoelectric switch | Germany | SICK |

Micro Switch | Taiwan | TEND |

Button and indicator light | France | SCHNEIDER |

touch screen | Taiwan | WEINVIEW |

Intermediate relay | Japan | OMRON |

IG line with gas filling online | ||

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close