2 Part Silicone Extruder Machine Secondary Sealing Machine For Double Glazing Machine

1.Single-function partsare equipped with manual functions, easy adjustment

Price

$12,000.00

Product Details

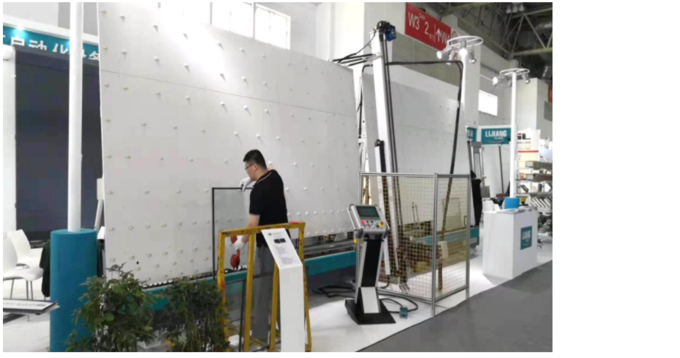

Silicone extruder machine Two-component Sealant-Spreading Machine LJST02A

insulating glass sealant

small extruder machine

sealant dispensing equipment

sealant dispensing machine

silicone extruder machine

Two-component Sealant-Spreading Machine was designed by advanced technology from abroad and inside of China.

Two-component Sealant-Spreading Machine is special equipment used for spreading the two-component polysulphide glue and/or two-component silicone structure

glue for the aluminum type insulating glass or curtain wall glass.

A and B pump in the Two-component Sealant-Spreading Machine adopt Korea brand HASCO.So it can ensure the reliable working-effect.

Special and convenient mixed device can ensure the high quality mixing of the two-component polysulphide glue and/or two-component silicone structure glue.

Two-component Sealant-Spreading Machine is featured by uniform mixture and continuous stability of extruded glue, good spreading effect and high production efficiency.

Two-component Sealant-Spreading Machine Main feature:

1.Min motor Adopted Korea HASCO to improve equipment efficiency.

2.B motor Adopted Korea HASCO to improve equipment efficiency.

3. Two-component Sealant-Spreading Machine adopted the Sealant gun from Korea HASCO.Stainless steel mix pipe and hybrid mandrel,easy to clean glue.

4.Special check valve in the pump to make sure extrude glue fluently and avoid incomplete mixing.

5.Gluing evenly without bubbles.

Vertical Insulating Glass Sealing Robot :

* Min & Max glass sizes can be optional

* Adopt 8 servo motors

* Adopt Japan ANCHUAN servo control systemwith stable performance

* Automaticallymeasure glass size, glue depth and glue speed with linear adjustment

* Adopt timingbelt to keep smooth convey with accurate position

* Sparesare produced with high standardization and high precision, ensure the machine can be used with long-term working

* The glass cornersare full without air bubbles, smooth surface, no need to

* Full automatic and high-efficiencymachine

* New scraper design, especially for making train IG with very even sides and corners, without any bubbles.

* Automatically repair glass corners with beautiful surface

* Smooth convey without scratchand pollution

* Single-function partsare equipped with manual functions, easy adjustment

* Shaped IG units (Optional)

* Stepped IG units with four sides (Optional)

* Double and Triple IG units

Other features

1. Filter out debris automatically through auto exhaust, keep spreading quickly and evenly.

2. Quickly speed of warming, improve work effect.

3. Adjustable coating speed, can up to 0-47m/min.

4. Can save about 40% materials, only 5g/m.

5. Extruder head height adjustment structure.

6. Automatic centering and clamping structure.

7. Stable temperature and it is convenient to adjust the sealing material automatically.

1. Filter out debris automatically through auto exhaust, keep spreading quickly and evenly.

2. Quickly speed of warming, improve work effect.

3. Adjustable coating speed, can up to 0-47m/min.

4. Can save about 40% materials, only 5g/m.

5. Extruder head height adjustment structure.

6. Automatic centering and clamping structure.

7. Stable temperature and it is convenient to adjust the sealing material automatically.

Argon gas filling machine is used to filling argon gas into double glazing glass units.

Significance of argon filling in double glazing glass production line

The significance of completing the argon filling of the insulating glass in the insulating glass production line (the argon filling operation is conducted at the pressure outlet of the laminating plate of the insulating glass production line, and the insulating glass enters the sealant production line after the argon filling operation to apply structural glue to the insulating glass) is that the argon filling process of the insulating glass is completed once in the laminating and sealant production line of the insulating glass. This process is relatively simple and efficient.

Features of using the argon gas filling machine in the double glazing glass production line

It is a precise way to inflate argon in the production line of insulating glass. This precise inflation method has a relatively fast inflation speed, greatly reducing the argon waste, making the cost of filling argon in the hollow glass very low. In the whole cost composition of the hollow glass, the cost of filling argon can almost be ignored, which is an efficient and economical inflation method.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close