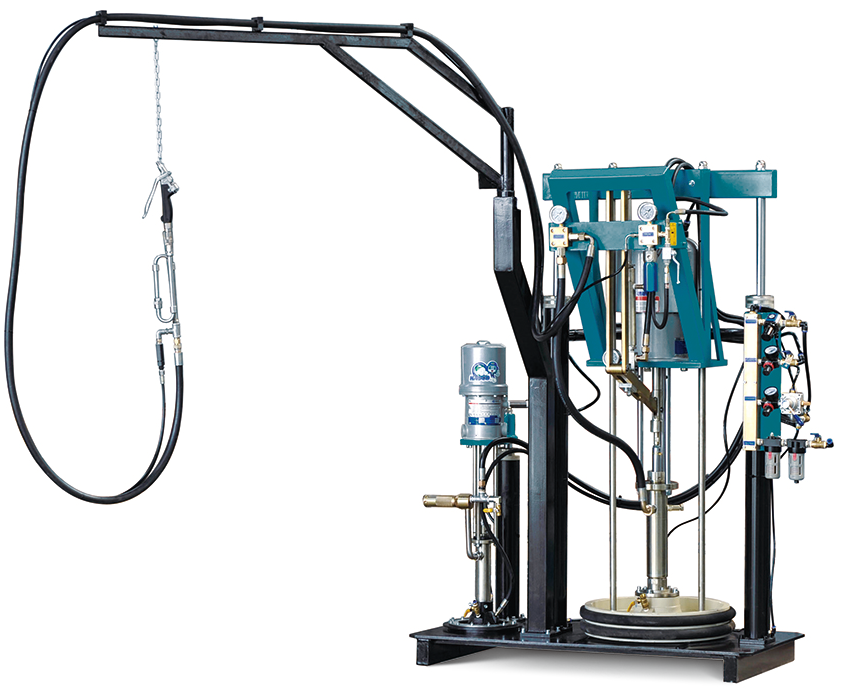

Insulating glass silicone sealant spreading equipment

1.Imported motor to improve equipment efficiency

2.Imported sealant gun,stainless steel mixer

3.High pressure protect device

4.Anti-back flow control structure

5. Mixed rate detector can control the rate of two kinds of glue

Price

$9,500.00

Product Details

Two-component glue coating machine is suitable for the last procedure of insulating glass production line, mainly used for two-component polysulfide glue, two-component silicone hollow glue coating. The machine can automatically complete the suction, mixing and output of two components of glue: and can adjust the proportion of two components according to the performance and use requirements of glue, adjust the curing speed to achieve the best use effect.

Two-component gluing machine is a new type of equipment developed by our company to meet the needs of insulating glass and glass curtain wall industry to provide high quality products. The machine is fully pneumatic controlled, without power access, and can be constructed on site. The operation is convenient, the work is stable and reliable, and only has the advantages of high coating efficiency, good mixing effect, stable flow of the output glue and stepless adjustment of the proportion of two kinds of components. It is an ideal supporting equipment for large-scale production of high-grade insulating glass and glass curtain wall products.

PARAMETER

Working air pressure | >0.6MPa |

Sealant spreading pressure | 15-20MPa |

Sealant volume | 4L/min |

Diameter of A/B sealant | 570mm/280mm |

Mixed rate | 6:1-14:1 |

Air supply | Flow 0.8m3/min |

Air pressure | >0.8MPa |

Overall dimension | 1700*1260*1900mm |

Weight | 600 kg |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close