* Minimum and maximum glass sizes for processing are optional

* 8 servomotors are adopted

* Yaskawa servo control system, stable performance

* Automatic measurement of glass size, glue speed, glue depth, linear adjustment

* Adopt synchronous belt, accurate position, smooth transmission

* High standardization of spare parts production, high precision, to ensure that the machine can be used for a long time

* Glass Angle full no bubbles, smooth surface.

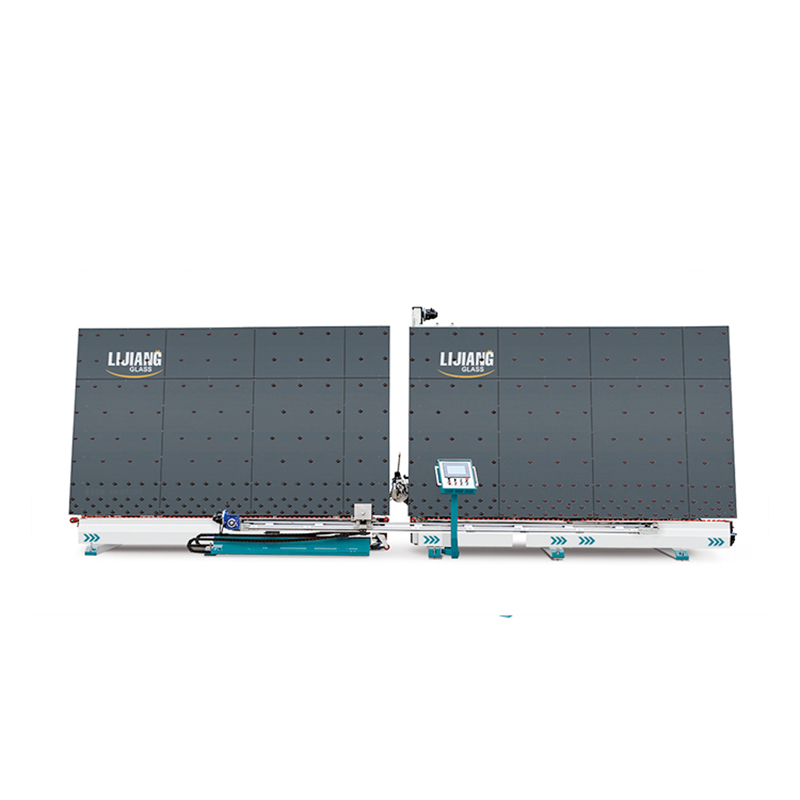

* Fully automatic and efficient machines

* New scraper design, especially suitable for making IG trains with very even sides and corners, without any bubbles.

* Automatic repair glass corner, beautiful surface

* Smooth transmission, no scratches, no pollution

* Single function parts with manual function, easy to adjust

* Special-shaped IG Unit (optional)

* Four-sided stepped IG unit (optional)

* Double and triple IG units

Smooth glue surface

High precision servo control system

Japan Yaskawa servo control system, clear wiring, to ensure the overall stable performance of the equipment.

Glass coating

Automatic measurement of glass size, coating speed, coating depth, through linear adjustment, to ensure the stability of insulating glass coating quality.

Rubber pump A and rubber pump B

When applying glue, glue pump A and B mix automatically to achieve automatic ratio.

Main technical parameters